Fujitsu AI Technology Helps

Prevent Sinkholes in Support of Kawasaki Geological Engineering’s Road Cavity

Surveys

Prevent Sinkholes in Support of Kawasaki Geological Engineering’s Road Cavity

Surveys

Kawasaki Geological

Engineering Co., Ltd., Fujitsu Limited, Fujitsu Traffic & Road Data Service

Limited

Engineering Co., Ltd., Fujitsu Limited, Fujitsu Traffic & Road Data Service

Limited

Tokyo, May 15, 2017

Kawasaki Geological Engineering Co., Ltd.,

Fujitsu Limited, and Fujitsu Traffic & Road Data Service Limited today

announced that Kawasaki Geological Engineering has leveraged Fujitsu’s AI

engine to develop subsurface cavity survey technology. Being able to more

accurately detect underground cavities that can cause sinkholes in roads, this

technology will be made available as a service beginning in the summer of 2017.

Fujitsu Limited, and Fujitsu Traffic & Road Data Service Limited today

announced that Kawasaki Geological Engineering has leveraged Fujitsu’s AI

engine to develop subsurface cavity survey technology. Being able to more

accurately detect underground cavities that can cause sinkholes in roads, this

technology will be made available as a service beginning in the summer of 2017.

Kawasaki Geological Engineering is using FUJITSU

Cloud Service K5 Zinrai Platform Service Zinrai Deep Learning —Fujitsu’s deep

learning platform service—to analyze and process the huge volume of radar

images collected with underground radar probe equipment. This increases the

efficiency of the search for underground cavities, which previously required

expert technicians to make visual determinations. In addition, by connecting

this technology with a service which displays the problem spots on a map—provided

by Fujitsu Traffic & Road Data Service—the positions of cavities beneath

road surfaces can be accurately understood, making the necessity of road

repairs clear to local governments.

Cloud Service K5 Zinrai Platform Service Zinrai Deep Learning —Fujitsu’s deep

learning platform service—to analyze and process the huge volume of radar

images collected with underground radar probe equipment. This increases the

efficiency of the search for underground cavities, which previously required

expert technicians to make visual determinations. In addition, by connecting

this technology with a service which displays the problem spots on a map—provided

by Fujitsu Traffic & Road Data Service—the positions of cavities beneath

road surfaces can be accurately understood, making the necessity of road

repairs clear to local governments.

Background

In Japan, there are about 3,300 incidents of

collapse caused by cavities under the surface of roads annually, making an

issue in society. The primary cause of these collapses is aging sewer pipes,

often located about three meters underground. This creates a growing need for a

system that can determine the risk of a collapse without excavating the road to

investigate.

collapse caused by cavities under the surface of roads annually, making an

issue in society. The primary cause of these collapses is aging sewer pipes,

often located about three meters underground. This creates a growing need for a

system that can determine the risk of a collapse without excavating the road to

investigate.

Currently, using underground radar probe

equipment developed by Kawasaki Geological Engineering, underground surveys,

which were previously limited to about one meter, can now be done to about five

meters deep, which is expected to significantly improve the reliability of

cavity explorations beneath road surfaces going forward. Because the massive

volume of image data collected by the underground radar probe equipment must be

visually evaluated by well-practiced expert technicians, however, there have

been issues with preserving objectivity and ever increasing workloads.

equipment developed by Kawasaki Geological Engineering, underground surveys,

which were previously limited to about one meter, can now be done to about five

meters deep, which is expected to significantly improve the reliability of

cavity explorations beneath road surfaces going forward. Because the massive

volume of image data collected by the underground radar probe equipment must be

visually evaluated by well-practiced expert technicians, however, there have

been issues with preserving objectivity and ever increasing workloads.

Figure 1:

Kawasaki Geological Engineering’s subsurface cavity identification technology

Kawasaki Geological Engineering’s subsurface cavity identification technology

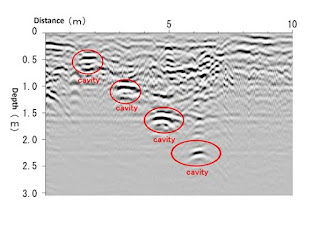

Figure 2:

Example of image data collected from the underground radar probe equipment

Example of image data collected from the underground radar probe equipment

Features of the Newly

Developed Technology

Developed Technology

Analysis and processing of the massive volume of

radar images taken with Kawasaki Geological Engineering’s world-leading underground

cavity detection technology will be carried out using image recognition through

the Zinrai Deep Learning platform service, which was launched by Fujitsu in

April 2017. The AI will be trained through machine learning on images where

changes in radar reflection are displayed as waveforms, and will then determine

whether they are cavities or sewer pipes.

radar images taken with Kawasaki Geological Engineering’s world-leading underground

cavity detection technology will be carried out using image recognition through

the Zinrai Deep Learning platform service, which was launched by Fujitsu in

April 2017. The AI will be trained through machine learning on images where

changes in radar reflection are displayed as waveforms, and will then determine

whether they are cavities or sewer pipes.

In a trial of cavity identification, in

comparison with existing visual identification by expert technicians, not only

was the cavity identification using AI able to accurately determine cavities

from image data, it did the analysis in one-tenth of the time.

comparison with existing visual identification by expert technicians, not only

was the cavity identification using AI able to accurately determine cavities

from image data, it did the analysis in one-tenth of the time.

Future Plans

Going forward, Kawasaki Geological Engineering

will link its AI-based subsurface cavity detection with unified services

visualizing investigated locations provided by Fujitsu Traffic & Road Data

Service, as well as continue to shrink and lighten its underground radar probe

equipment, with the goal of commercializing it as a service that can broadly

automate measurement tasks for organizations such as local governments,

supporting more efficient road maintenance management.

will link its AI-based subsurface cavity detection with unified services

visualizing investigated locations provided by Fujitsu Traffic & Road Data

Service, as well as continue to shrink and lighten its underground radar probe

equipment, with the goal of commercializing it as a service that can broadly

automate measurement tasks for organizations such as local governments,

supporting more efficient road maintenance management.

In addition, Kawasaki Geological Engineering

will work to expand its cutting-edge subsurface cavity identification

technology around the globe, beyond just Japan, to help prevent road collapses

which are becoming an issue in society.

will work to expand its cutting-edge subsurface cavity identification

technology around the globe, beyond just Japan, to help prevent road collapses

which are becoming an issue in society.

For the LATEST tech updates,

FOLLOW us on our Twitter

LIKE us on our FaceBook

SUBSCRIBE to us on our YouTube Channel!