Fujitsu and INESA Group Collaborate on Smart

Manufacturing Project for “Made in China 2025”

Fujitsu Limited,Fujitsu (China) Holdings Co., Ltd.,INESA (Group)

Co., Ltd.

(China) Holdings Co., Ltd., and INESA (Group) Co., Ltd.(1), a large-scale,

state-owned company in China that provides smart city solutions, today

announced that they are collaborating on a Smart Manufacturing Project known as

“Made in China 2025,”(2) a strategic framework which aims to

strengthen competitiveness in manufacturing.In response to the rapid changes in corporate

business models and the market environment, the government of China has set

forth “Made in China 2025”, which aims to combine cutting-edge ICT

with manufacturing, shifting China from a manufacturing giant that

mass-produces products to a manufacturing powerhouse that focuses on production

quality. In the midst of this effort, using their abundant experience in the

ICT and manufacturing fields, Fujitsu and INESA Group are jointly promoting

their Smart Manufacturing Project, contributing to realizing the “Made in

China 2025” plan.

As a member of a group of large-scale, state-run

companies under the jurisdiction of the State-owned Assets Supervision and

Administration Commission of Shanghai Municipal Government, INESA Group has a

history in the electronics manufacturing industry of more than fifty years. In

order to adapt to the innovations of recent years, INESA Group, while

manufacturing, is driving the development of the information industry, and has

established the strategic goal of contributing to the building of smart cities

as its business model, working to create a new industry that fuses ICT and

manufacturing.

At a color-filter manufacturing plant of INESA

Display Materials Co., Ltd., an INESA Group company, Fujitsu established a plan

to turn the plant into a smart factory suited to current operations, by

studying current processes and issues. Based on information from existing

automated production lines and manufacturing management systems, Fujitsu is

connecting the entire manufacturing process, including product manufacturing

processes and production line placement, with technologies, such as big data

and IoT. This is to achieve digital transformation, building a system that

visualizes the efficiency of the factory with the use of tools such as

Fujitsu’s sensors, network technologies, a dashboard solution, and a big data

analysis platform, to advance INESA Group’s move toward smart manufacturing.

The three companies began this project in January

of 2016, and aim to complete it in 2018. In the first stage of this project,

Fujitsu organized and improved INESA Group’s existing information systems,

advanced the deployment of IoT in the factory, and built a big data analysis

platform. As a result, it has become possible to share data within the factory

and visualize operations in real time. The constructed platform will support

higher levels of factory intelligence in the future.

The specific initiatives implemented under the

current project are as follows:

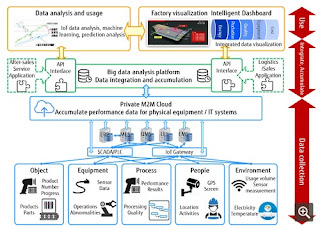

Figure: Overview of smart manufacturing project

– Building IoT platforms that utilize data in the

factory

Using Fujitsu’s unique intelligent network

communications technologies, the companies have improved the slow and unstable

communication in the existing large-scale network, building a low-cost system

to automatically collect energy consumption data, including for electricity,

water and gas. In addition, by collecting and managing data through the IoT

platform, energy consumption has been reduced, supporting the realization of a

green factory.

– Building a big data analysis platform

This system aggregates and centralizes the

manufacturing progress data collected through the IoT platform, such as from

sensors. This aggregated big data is processed and analyzed in real time under

advanced security, enabling the detection of warning signs of problems in

manufacturing equipment.

– Building a system for visualizing efficiencies

throughout the factory

Using FUJITSU Enterprise Application Intelligent

Dashboard, Fujitsu Limited’s solution that supports the overall optimization of

factories, with the big data analysis platform, this system displays important

key performance indicators, such as manufacturing, energy consumption, quality,

facilities status, and expenses, in an integrated fashion. At the same time, it

monitors the status of the production lines in real time, visualizing the

efficiency of the factory as a whole.

– Establishing standards for evaluating the degree

of maturity of the smart factory

Fujitsu assisted in formulating standards and an

evaluation model for the degree of maturity of INESA Group’s smart factory

using the three criteria of technology, implementation, and integration, based

on INESA Group’s definitions and goals for smart manufacturing. In addition,

during this smart manufacturing model factory project with INESA Group, the

companies are carrying out studies and evaluations, extracting content and

technology common across the industry and standardizing it, aiming to

popularize a shared INESA Group standard within the industry.

Figure: The Intelligent Dashboard visualizing the

operational status of production lines for the entire factory (Location:

Central monitoring room in INESA Display Materials Co., Ltd.’s color-filter

manufacturing plant).

Using the Fujitsu Limited Intelligent Dashboard to

visualize efficiency for the factory as a whole, managers can control the

operational status of the manufacturing lines across the entire factory from

the factory’s central monitoring room. The project’s first stage of development

has now gone online, and is already producing results in actual production

management. For example, a great deal of time used to be spent on such tasks as

collecting production status and statistical data, but with Fujitsu’s

Intelligent Dashboard, it has become possible to intuitively grasp the

situation. This can be expected to play a significant role in improvements in

productivity and management going forward.

Owing to its cutting-edge technologies and as a

model initiative for the industry, this project was chosen as a Smart Factory

Model Project for 2016 in an evaluation by the Chinese Ministry of Industry and

Information Technology. Fujitsu and INESA Group will continue to contribute to

the digital transformation in China’s manufacturing industry going forward.

In addition, the three companies, as strategic

partners, will spread this successful model to more manufacturing companies in

China, working together to achieve the goals of “Made in China 2025.”

Comment from Cai Xiaoqing, President of INESA Group

INESA Group is focusing its efforts on creating

smart factories, positioning this business as a core infrastructure business

supporting INESA Group’s smart cities, while also advancing initiatives in our

factories.

Through this project, by working with Fujitsu, I

believe we will meet the business transformation needs of our many customers in

the manufacturing industry, and contribute to transforming the manufacturing

industry of China.

(1) INESA (Group) Co., Ltd.

Official Website: http://www.inesa.com/index.html

(2) Made in China 2025

On May 8, 2015, China’s State Council unveiled its

first 10-year national plan for transforming China’s manufacturing, entitled

“Made in China 2025.” The plan is designed to put China on a new path

to industrialization, with greater emphasis on innovation, expanded use of

new-generation information technology, intelligent manufacturing, consolidation

of the industrial base, integration of industrial processes and systems, and a

robust multilayer talent development structure. Measures taken in this respect

will facilitate China’s transformation from a manufacturing giant with a focus

on quantity to one with a qualitative edge.

For the LATEST tech updates,

FOLLOW us on our Twitter

LIKE us on our FaceBook

SUBSCRIBE to us on our YouTube Channel!