Tuesday 5 April 2016

Electrically conductive adhesives enabling low temperature

electronics

IDTechEx

Cambridge, UK

Electrically conductive adhesives enabling low temperature

electronics

IDTechEx

Cambridge, UK

Electrically conductive adhesives enabling low temperature

electronics

electronics

By Rachel Gordon, Technology Analyst, IDTechEx

Materials are needed to replace the estimated 50,000 metric tons

of tin-lead solder currently used each year, but there are no

“drop-in” replacements for eutectic tin-lead solder. $1.2 billion of

electrically conductive adhesives (ECAs) are already selling each year, and

they are becoming increasingly common to replace solders in a variety of

functions, applications and industries. The new IDTechEx Research report Electrically Conductive Adhesives 2016-2026 covers

the three main categories of conductive adhesives available as safe and

environmentally-sound solder alternatives.

of tin-lead solder currently used each year, but there are no

“drop-in” replacements for eutectic tin-lead solder. $1.2 billion of

electrically conductive adhesives (ECAs) are already selling each year, and

they are becoming increasingly common to replace solders in a variety of

functions, applications and industries. The new IDTechEx Research report Electrically Conductive Adhesives 2016-2026 covers

the three main categories of conductive adhesives available as safe and

environmentally-sound solder alternatives.

ECAs consist of a polymeric resin (such as an epoxy, or a

silicone) that provides physical and mechanical properties such as adhesion,

mechanical strength and impact strength, and a metal filler (such as

silver, gold or nickel) that conducts electricity. In order to reduce the

volume of filler used, increase the electrical conductivity, and decrease the

finest possible pitch width, there is research into using nanoparticle fillers

including silver nanowires, silver nanoparticles, nickel nanoparticles and

carbon nanotubes.

silicone) that provides physical and mechanical properties such as adhesion,

mechanical strength and impact strength, and a metal filler (such as

silver, gold or nickel) that conducts electricity. In order to reduce the

volume of filler used, increase the electrical conductivity, and decrease the

finest possible pitch width, there is research into using nanoparticle fillers

including silver nanowires, silver nanoparticles, nickel nanoparticles and

carbon nanotubes.

Figure 1: Diagram showing some of the most important parameters

to consider when choosing an electrically conductive adhesive. Source: IDTechEx

Research report Electrically Conductive Adhesives 2016-2026 (www.IDTechEx.com/adhesives).

to consider when choosing an electrically conductive adhesive. Source: IDTechEx

Research report Electrically Conductive Adhesives 2016-2026 (www.IDTechEx.com/adhesives).

Obviously in all these materials, the electrical conductivity is

of primary importance. However, the thermal conductivity must also be high

enough so that components do not overheat. The thermal conductivity of ICP is

approximately 20 W/m.K, compared to 60 W/m.Kfor lead solders. Adhesion to the

mating surfaces must be good enough that there will not be adhesive failure,

and the tensile strength must be high enough to avoid cohesive failure, even

under bending and flexing conditions. The viscosity must be low enough for

easy dispensing, but high enough after curing to avoid pump out and dry out. In

some applications, the operating temperature will be important and, whereas

solders can operate up to 270ºC, ECAs are limited to around 200ºC. It must be

non-toxic, because there is no point replacing lead with another equally toxic

material.

of primary importance. However, the thermal conductivity must also be high

enough so that components do not overheat. The thermal conductivity of ICP is

approximately 20 W/m.K, compared to 60 W/m.Kfor lead solders. Adhesion to the

mating surfaces must be good enough that there will not be adhesive failure,

and the tensile strength must be high enough to avoid cohesive failure, even

under bending and flexing conditions. The viscosity must be low enough for

easy dispensing, but high enough after curing to avoid pump out and dry out. In

some applications, the operating temperature will be important and, whereas

solders can operate up to 270ºC, ECAs are limited to around 200ºC. It must be

non-toxic, because there is no point replacing lead with another equally toxic

material.

Lead solder melts at 215ºC, whereas isotropic conductive paste

can be cured as low as 110ºC. This opens up possibilities for using plastic

substrates to allow a new generation of flexible electronics. In order to use

PET substrates, without the risk of buckling or warping during curing, the cure

temperature needs to be brought below 80ºC.

can be cured as low as 110ºC. This opens up possibilities for using plastic

substrates to allow a new generation of flexible electronics. In order to use

PET substrates, without the risk of buckling or warping during curing, the cure

temperature needs to be brought below 80ºC.

Key applications

·

Photovoltaic modules –

ECAs have suffered from poor stability when applied to copper and tin metals,

but improved ECAs for PV applications have been available since 2010. Lower

temperature interconnections can allow thinner wafers, and reduce warpage and

breakage of solar cells.

Photovoltaic modules –

ECAs have suffered from poor stability when applied to copper and tin metals,

but improved ECAs for PV applications have been available since 2010. Lower

temperature interconnections can allow thinner wafers, and reduce warpage and

breakage of solar cells.

·

LCD and OLED displays –

ACFs have found a particular niche market in packaging flat panel displays. In

general, bending or physical deformation of ECAs can degrade the electrical

conductivity. Therefore, novel flexible electrically conductive materials which

respond well to repeated bending or high elongations will be required

for future flexible display technologies.

LCD and OLED displays –

ACFs have found a particular niche market in packaging flat panel displays. In

general, bending or physical deformation of ECAs can degrade the electrical

conductivity. Therefore, novel flexible electrically conductive materials which

respond well to repeated bending or high elongations will be required

for future flexible display technologies.

·

Touch panels – The damage

to the substrates can be reduced by lowering the bonding temperature during

assembly. The penetration of touch panels in the cell phone market is

forecasted to reach more than 40% in the near future.

Touch panels – The damage

to the substrates can be reduced by lowering the bonding temperature during

assembly. The penetration of touch panels in the cell phone market is

forecasted to reach more than 40% in the near future.

·

LEDs – It is quick and

cheap to mount LEDs using conductive adhesives and the thermal penalty is

tolerable if the adhesive layer is kept thin.

LEDs – It is quick and

cheap to mount LEDs using conductive adhesives and the thermal penalty is

tolerable if the adhesive layer is kept thin.

·

RFID chips – Conductive

adhesives are used for mounting temperature-sensitive chips on smart cards,

because of low curing temperatures.

RFID chips – Conductive

adhesives are used for mounting temperature-sensitive chips on smart cards,

because of low curing temperatures.

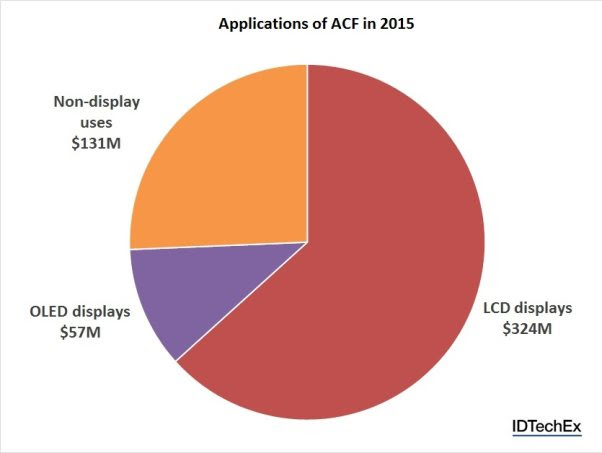

Figure 2: Chart showing the ACF market share in 2015 by

application. Source: IDTechEx Research report Electrically Conductive Adhesives 2016-2026 (www.IDTechEx.com/adhesives).

application. Source: IDTechEx Research report Electrically Conductive Adhesives 2016-2026 (www.IDTechEx.com/adhesives).

Currently, 74% of Anisotropic Conductive Film (ACF) is used in

the manufacture of LCD or OLED displays. Displays are becoming more widely used

in consumer electronics, aerospace, defence, automotive, and infrastructure

sectors. UV-thermal cure mechanisms must be developed to lower cure temperature

to allow plastic substrates for flexible displays. However, according to

IDTechEx Research’s report Electrically Conductive Adhesives 2016-2026, this

market is still set to diversify with the market for ACF in non-display

applications reaching over $1 billion by 2026, due to the reliable properties,

thinness and ease of processing. Metallic coatings on polymeric particles will

allow lower cost fillers.

the manufacture of LCD or OLED displays. Displays are becoming more widely used

in consumer electronics, aerospace, defence, automotive, and infrastructure

sectors. UV-thermal cure mechanisms must be developed to lower cure temperature

to allow plastic substrates for flexible displays. However, according to

IDTechEx Research’s report Electrically Conductive Adhesives 2016-2026, this

market is still set to diversify with the market for ACF in non-display

applications reaching over $1 billion by 2026, due to the reliable properties,

thinness and ease of processing. Metallic coatings on polymeric particles will

allow lower cost fillers.

Electrically Conductive Adhesives 2016-2026 offers

worldwide coverage of electrically conductive adhesives, most of which are

manufactured in Asia-Pacific but start-ups and innovation exists in Europe and

North America. The report is based on extensive research and includes twelve

primary interviews with the market leading manufacturers. It includes forecasts

by revenue, split by technology and function, until 2026.

worldwide coverage of electrically conductive adhesives, most of which are

manufactured in Asia-Pacific but start-ups and innovation exists in Europe and

North America. The report is based on extensive research and includes twelve

primary interviews with the market leading manufacturers. It includes forecasts

by revenue, split by technology and function, until 2026.

For the LATEST tech updates,

FOLLOW us on our Twitter

LIKE us on our FaceBook

SUBSCRIBE to us on our YouTube Channel!