NEC launches new PLM software product

Obbligato III R4.1

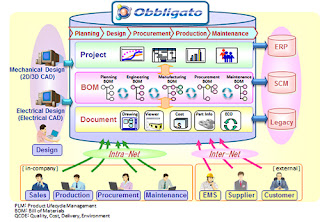

Tokyo, June 10, 2016 – NEC Corporation (NEC; TSE: 6701) today

announced the launch of Obbligato III R4.1, the latest version of its Obbligato

III Product Lifecycle Management (PLM) software, which consolidates the

management of product technology data such as design drawings, specifications and

bills of material (BOM).

announced the launch of Obbligato III R4.1, the latest version of its Obbligato

III Product Lifecycle Management (PLM) software, which consolidates the

management of product technology data such as design drawings, specifications and

bills of material (BOM).

Obbligato III R4.1 manages not only existing BOM for part types and

quantities, but also bills of process (BOP) for manufacturing processes,

equipment used and others, thereby promoting the sharing and succession of

process charts, operating instructions and other manufacturing knowledge. M

quantities, but also bills of process (BOP) for manufacturing processes,

equipment used and others, thereby promoting the sharing and succession of

process charts, operating instructions and other manufacturing knowledge. M

Furthermore, consolidating the management of BOM and BOP enables the

influence of specification changes and faults to be identified promptly, not

only with respect to parts, but also with respect to processes and equipment,

and to be addressed in a timely manner. Ensuring the consistency of

manufacturing quality (monozukuri) expedites the start-up of new global

manufacturing sites and contributes to the transfer of production. Moreover,

the continual improvement of BOP to optimize aspects such as production line

configuration and equipment setup requirements by analyzing disparities between

BOP and real time output from sensors using the Internet of Things (IoT)

maximizes the performance of manufacturing sites.

influence of specification changes and faults to be identified promptly, not

only with respect to parts, but also with respect to processes and equipment,

and to be addressed in a timely manner. Ensuring the consistency of

manufacturing quality (monozukuri) expedites the start-up of new global

manufacturing sites and contributes to the transfer of production. Moreover,

the continual improvement of BOP to optimize aspects such as production line

configuration and equipment setup requirements by analyzing disparities between

BOP and real time output from sensors using the Internet of Things (IoT)

maximizes the performance of manufacturing sites.

In addition, NEC has added new management functions in order to comply

with the United States Code of Federal Regulations “21 CFR Part 820,”

pertaining to the quality of systems, as established by the U.S. Food and Drug

Administration (FDA) for medical device manufacturers.

with the United States Code of Federal Regulations “21 CFR Part 820,”

pertaining to the quality of systems, as established by the U.S. Food and Drug

Administration (FDA) for medical device manufacturers.

“With many companies managing BOP with paper or Excel files, and with

the retirement of many industrial engineers, the sharing and succession of

manufacturing knowledge is a major challenge,” said Toshikazu Fukuoka, General

Manager, Manufacturing and Process Industries Systems Development Division, NEC

Corporation. “Obbligato III’s enhancements respond to this challenge by helping

to maintain consistency of manufacturing quality on a global scale with the

standardization of BOP.”

the retirement of many industrial engineers, the sharing and succession of

manufacturing knowledge is a major challenge,” said Toshikazu Fukuoka, General

Manager, Manufacturing and Process Industries Systems Development Division, NEC

Corporation. “Obbligato III’s enhancements respond to this challenge by helping

to maintain consistency of manufacturing quality on a global scale with the

standardization of BOP.”

Please refer to the following for more details of Obbligato III R4.1.

For the LATEST tech updates,

FOLLOW us on our Twitter

LIKE us on our FaceBook

SUBSCRIBE to us on our YouTube Channel!