Towards a seamless integration of

the physical and virtual worlds

the physical and virtual worlds

By Norbert

Aschenbrenner / Frank Krull, Siemens

Aschenbrenner / Frank Krull, Siemens

Our day-to-day lives are being filled with

more and more devices that let users find out the status of an object via the

Internet or the Cloud. Examples of this trend include fitness-trackers, sensors

that monitor plants’ moisture levels, and houses that learn to set their heat

and lighting to f

more and more devices that let users find out the status of an object via the

Internet or the Cloud. Examples of this trend include fitness-trackers, sensors

that monitor plants’ moisture levels, and houses that learn to set their heat

and lighting to f

it their residents’ living patterns. As this process evolves,

it is realistic to expect that eventually every “thing” will be equipped with

an Internet address, thus opening up whole new ways to interact with those “things.”

This paradigm of the Internet of Things (IoT) opens up immense opportunities for

Siemens. After all, Siemens is a major player in combining hardware and

software – for example, in automation solutions for production, in rail and

traffic management systems, and in the decentralized delivery of electric

power.

Siemens. After all, Siemens is a major player in combining hardware and

software – for example, in automation solutions for production, in rail and

traffic management systems, and in the decentralized delivery of electric

power.

All the same, factories, traffic networks and

utility grids are a good deal more complex than smartphones and fitness tracker.

All are examples of real and virtual systems that have been intermeshed and

that often even involve critical infrastructures. Customers in such critical

areas have entirely different expectations about safety, reliability and

durability than those purchasing a smart thermostat or plant moisture tracking

system. What’s more, such customers want to enrich their existing equipment

through the advantages of the evolving digital universe without endangering or

sacrificing either data protection or intellectual property.

utility grids are a good deal more complex than smartphones and fitness tracker.

All are examples of real and virtual systems that have been intermeshed and

that often even involve critical infrastructures. Customers in such critical

areas have entirely different expectations about safety, reliability and

durability than those purchasing a smart thermostat or plant moisture tracking

system. What’s more, such customers want to enrich their existing equipment

through the advantages of the evolving digital universe without endangering or

sacrificing either data protection or intellectual property.

That’s why Siemens has expanded the concept

of the Internet of Things for industrial applications to create the Web of

Systems, meaning systems that are digital, communicate with each other, and can

act autonomously. Siemens’ vision is that as this ecosystem takes shape its

elements will be managed via future Web technologies that use standardized

protocols and languages of the kind that are used for the Internet today.

of the Internet of Things for industrial applications to create the Web of

Systems, meaning systems that are digital, communicate with each other, and can

act autonomously. Siemens’ vision is that as this ecosystem takes shape its

elements will be managed via future Web technologies that use standardized

protocols and languages of the kind that are used for the Internet today.

This linking up of the real world and the

virtual world of data offers multiple advantages for Siemens customers. It

enables them to capture and analyze the current status of a system and its

parts anytime, in detail. This in turn yields immense opportunities for savings

through predictive maintenance, as well as major potential for optimizing

systems. Using today’s technologies from the World Wide Web environment,

systems can often be implemented and commissioned faster and more economically.

A system’s intelligence can be distributed as needed between real components

and virtual systems in the Cloud, resulting in enhanced robustness and customer

data protection.

virtual world of data offers multiple advantages for Siemens customers. It

enables them to capture and analyze the current status of a system and its

parts anytime, in detail. This in turn yields immense opportunities for savings

through predictive maintenance, as well as major potential for optimizing

systems. Using today’s technologies from the World Wide Web environment,

systems can often be implemented and commissioned faster and more economically.

A system’s intelligence can be distributed as needed between real components

and virtual systems in the Cloud, resulting in enhanced robustness and customer

data protection.

Finally, as the digital landscape is

transformed along these lines, it will become easier to update systems with new

functions, or to update system software on the fly, in much the same way as

smartphones and other devices are updated through apps.

transformed along these lines, it will become easier to update systems with new

functions, or to update system software on the fly, in much the same way as

smartphones and other devices are updated through apps.

Why

Smart Grids Need Distribution Transformers

One of many examples where our Web of Systems

offers advantages is smart grids. Until just a few years ago, electric power

grids were organized in a strict hierarchy. But today they’ve become

decentralized systems. Photovoltaic installations and other renewable energy

sources feed electricity into the grid on an unregulated, fluctuating basis, at

voltage levels that used to apply only to consumers, not generators. In a

worst-case scenario, that can make a grid unstable.

offers advantages is smart grids. Until just a few years ago, electric power

grids were organized in a strict hierarchy. But today they’ve become

decentralized systems. Photovoltaic installations and other renewable energy

sources feed electricity into the grid on an unregulated, fluctuating basis, at

voltage levels that used to apply only to consumers, not generators. In a

worst-case scenario, that can make a grid unstable.

So grids have to be given the ability to

counteract that shifting environment. One component here is distribution

transformers that can adjust independently and cooperatively to smooth out

voltage fluctuations within their local areas. But for that they need their own

intelligence and communication capability – in other words, they need to be

“smart” and networked. And this is where one important difference from the

typical Internet of Things scenario comes in. The Internet of Things is

connected to the Cloud, and the Cloud is where the data – for example from the

equipment’s sensors – is primarily processed. Response times and reliability

are often a secondary priority. But in a Web of Systems, things themselves have

intelligence. They can respond locally, fast, and reliably, while at the same

time drawing on the power of the Cloud for optimization.

counteract that shifting environment. One component here is distribution

transformers that can adjust independently and cooperatively to smooth out

voltage fluctuations within their local areas. But for that they need their own

intelligence and communication capability – in other words, they need to be

“smart” and networked. And this is where one important difference from the

typical Internet of Things scenario comes in. The Internet of Things is

connected to the Cloud, and the Cloud is where the data – for example from the

equipment’s sensors – is primarily processed. Response times and reliability

are often a secondary priority. But in a Web of Systems, things themselves have

intelligence. They can respond locally, fast, and reliably, while at the same

time drawing on the power of the Cloud for optimization.

How

to Keep a Secret

In order to realize the vision of a Web of

Systems, associated software has to be able to understand the data, so it can

derive intelligent conclusions from it. And that’s possible only if information

that describes the data’s meaning is either already present or supplied

alongside it. Human experts can respond to this kind of challenge because they understand

the context in which data is embedded. But software has to be told the context

explicitly. Yet that context includes important information about the system in

question and its associated processes, which in many cases are valuable

business secrets that an operator would be very unwilling to deliver unfiltered

into the Cloud. In view of this, it is better if machines can draw conclusions

themselves, locally, so that the context remains protected. With regard to

distribution transformers, for instance, they can assess independently whether

to smooth out a critical grid state or whether they will need help from a

higher level, thus ensuring a high level of data protection by restricting

secrets to local systems.

Systems, associated software has to be able to understand the data, so it can

derive intelligent conclusions from it. And that’s possible only if information

that describes the data’s meaning is either already present or supplied

alongside it. Human experts can respond to this kind of challenge because they understand

the context in which data is embedded. But software has to be told the context

explicitly. Yet that context includes important information about the system in

question and its associated processes, which in many cases are valuable

business secrets that an operator would be very unwilling to deliver unfiltered

into the Cloud. In view of this, it is better if machines can draw conclusions

themselves, locally, so that the context remains protected. With regard to

distribution transformers, for instance, they can assess independently whether

to smooth out a critical grid state or whether they will need help from a

higher level, thus ensuring a high level of data protection by restricting

secrets to local systems.

Although localized, this information can

nevertheless be used to generate value – for example by using predictive

maintenance or developing new services. To make use of this and other data from

industrial systems, trains or gas turbines, Siemens relies on Sinalytics. This

is a new platform for industrial data analysis that makes it possible to offer

new digital services to every customer. Sinalytics processes data from many

different distributed systems and their sensors in real time and also supports

local data processing directly in devices.

nevertheless be used to generate value – for example by using predictive

maintenance or developing new services. To make use of this and other data from

industrial systems, trains or gas turbines, Siemens relies on Sinalytics. This

is a new platform for industrial data analysis that makes it possible to offer

new digital services to every customer. Sinalytics processes data from many

different distributed systems and their sensors in real time and also supports

local data processing directly in devices.

The

Road to Self-Stabilizing Grids

Another advantage of the Web of Systems

approach is that it opens the door to a platform approach in which functions

can be distributed and installed like apps, and run in much the same way. For

example, services can easily be distributed that make the systems environment

more attractive not just for Siemens, but for its customers and even their own

customers. In such an environment, a distribution transformer could, for

instance, run applications for energy-efficient management of neighborhood

street lighting. When an update is due or a new function is needed, the

software can be uploaded remotely.

approach is that it opens the door to a platform approach in which functions

can be distributed and installed like apps, and run in much the same way. For

example, services can easily be distributed that make the systems environment

more attractive not just for Siemens, but for its customers and even their own

customers. In such an environment, a distribution transformer could, for

instance, run applications for energy-efficient management of neighborhood

street lighting. When an update is due or a new function is needed, the

software can be uploaded remotely.

The smart distribution transformer – a new

Siemens development – is already being used in practice for voltage regulation

in the low-voltage grid, and is thus a key part of a future system known as an

intelligent secondary substation node (iSSN). With its computing power and

optional communication connection, the iSSN will provide the possibility for

far more than supplying households with the right voltage. It will enable the

power grid to cope with additional feed-ins or loads with no need for massive

infrastructure expansions.

Siemens development – is already being used in practice for voltage regulation

in the low-voltage grid, and is thus a key part of a future system known as an

intelligent secondary substation node (iSSN). With its computing power and

optional communication connection, the iSSN will provide the possibility for

far more than supplying households with the right voltage. It will enable the

power grid to cope with additional feed-ins or loads with no need for massive

infrastructure expansions.

This iSSN is currently being developed

further in the context of the Web of Systems project. Its Web connection, for

example, will make it significantly easier to commission, maintain, and update

it. And each such substation will supply a wealth of data that will make it

possible to identify potentially destabilizing grid conditions, thus providing

an important additional tool for predictive power grid planning.

further in the context of the Web of Systems project. Its Web connection, for

example, will make it significantly easier to commission, maintain, and update

it. And each such substation will supply a wealth of data that will make it

possible to identify potentially destabilizing grid conditions, thus providing

an important additional tool for predictive power grid planning.

But a distribution transformer doesn’t add up

to a Web of Systems all by itself. The other components in the electric network

– meters, building distribution systems, photovoltaic systems, electric cars –

must also be equipped with sensors, local intelligence, and the ability to

communicate. That is already becoming the case. For Siemens, that means new

opportunities in virtually every one of the sectors in which it does business.

to a Web of Systems all by itself. The other components in the electric network

– meters, building distribution systems, photovoltaic systems, electric cars –

must also be equipped with sensors, local intelligence, and the ability to

communicate. That is already becoming the case. For Siemens, that means new

opportunities in virtually every one of the sectors in which it does business.

Webs

of Systems that are already Operational

Siemens is already using Webs of Systems to

implement solutions that used to involve a great deal of engineering or

installation work. One example is the electric bus charging system that Siemens

has installed in a number of European cities. Here, everything from bus

electronics and fast charging stations to the management backend systems

communicate over the Web in order to coordinate and optimize the charging

process.

implement solutions that used to involve a great deal of engineering or

installation work. One example is the electric bus charging system that Siemens

has installed in a number of European cities. Here, everything from bus

electronics and fast charging stations to the management backend systems

communicate over the Web in order to coordinate and optimize the charging

process.

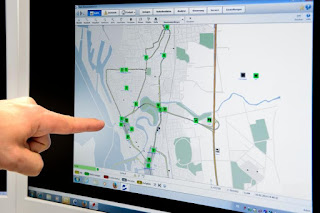

Another example is the optimization of water

distribution networks with a sensor network that detects leaks and minimizes

pumps’ energy consumption. An important point here is that data integration is

taking place in the context of existing control systems. Siemens is looking at

similar situations in many other existing installations. The reason for this is

clear: customers want the reliability and flexibility that are the hallmarks of

advanced digital systems. The Web of Systems can be the essential key to

opening up these benefits.

distribution networks with a sensor network that detects leaks and minimizes

pumps’ energy consumption. An important point here is that data integration is

taking place in the context of existing control systems. Siemens is looking at

similar situations in many other existing installations. The reason for this is

clear: customers want the reliability and flexibility that are the hallmarks of

advanced digital systems. The Web of Systems can be the essential key to

opening up these benefits.

For the LATEST tech updates,

FOLLOW us on our Twitter

LIKE us on our FaceBook

SUBSCRIBE to us on our YouTube Channel!