ROBOTICS MEETS

ADDITIVE MANUFACTURING

ADDITIVE MANUFACTURING

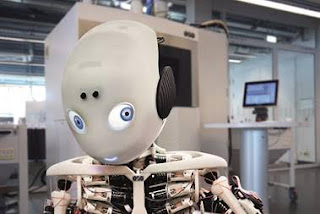

EOS sponsors the Roboy research project which aims to

advance humanoid robotics to the capability of human bodies.

advance humanoid robotics to the capability of human bodies.

Singapore, 15 February, 2017 – EOS, the global

technology and quality leader for high-end Additive Manufacturing (AM)

solutions, has announced its support of the Swiss society Devanthro and the

Roboy project at the Technical University of Munich. The goal of the Roboy

project is to advance humanoid robotics to the capability of human bodies. The

vision is to iteratively improve Roboy models until the performance is

comparable to humans in dexterity, robustness and flexibility.

technology and quality leader for high-end Additive Manufacturing (AM)

solutions, has announced its support of the Swiss society Devanthro and the

Roboy project at the Technical University of Munich. The goal of the Roboy

project is to advance humanoid robotics to the capability of human bodies. The

vision is to iteratively improve Roboy models until the performance is

comparable to humans in dexterity, robustness and flexibility.

The first prototype – Roboy Junior –

has muscles and tendons rather than motors in the joints. It has been developed

under substantial usage of AM: The complete skeletal body structure of Roboy,

which encases his bones and muscles, has been built with EOS systems for

Plastic Additive Manufacturing. The use of Industrial 3D Printing has several

key advantages; among them is the possibility of building complex functional

geometries as well as sustaining a fast and iterative hardware development.

has muscles and tendons rather than motors in the joints. It has been developed

under substantial usage of AM: The complete skeletal body structure of Roboy,

which encases his bones and muscles, has been built with EOS systems for

Plastic Additive Manufacturing. The use of Industrial 3D Printing has several

key advantages; among them is the possibility of building complex functional

geometries as well as sustaining a fast and iterative hardware development.

Values of Additive Manufacturing

Additive Manufacturing allows for

highly complex structures which are also extremely light and stable. It

provides a high degree of design freedom, optimization and integration of

functional features, and the manufacture of small batch sizes at economical

unit costs. The Roboy development benefits from all these advantages: Building

complex functional geometries without classical fabrication constraints allows

the Roboy team to implement functionality directly into the geometrical parts.

Consequently, build complexity is reduced, and many of the otherwise necessary

assembly steps can be dispensed of. For example, Roboy’s hands and forearms are

manufactured in one piece, including several joints and individual phalanxes

for each finger.

highly complex structures which are also extremely light and stable. It

provides a high degree of design freedom, optimization and integration of

functional features, and the manufacture of small batch sizes at economical

unit costs. The Roboy development benefits from all these advantages: Building

complex functional geometries without classical fabrication constraints allows

the Roboy team to implement functionality directly into the geometrical parts.

Consequently, build complexity is reduced, and many of the otherwise necessary

assembly steps can be dispensed of. For example, Roboy’s hands and forearms are

manufactured in one piece, including several joints and individual phalanxes

for each finger.

Due to Roboy’s maximal mechatronic

complexity on a minimal space, it is not possible to validate some project

requirements in simulation. Therefore, the development team needs to be able to

test the robot itself. AM is key to this because it allows the fast

manufacturing of individual components and the modularization and

parameterization of the robot’s construction, enabling an iterative hardware

development.

complexity on a minimal space, it is not possible to validate some project

requirements in simulation. Therefore, the development team needs to be able to

test the robot itself. AM is key to this because it allows the fast

manufacturing of individual components and the modularization and

parameterization of the robot’s construction, enabling an iterative hardware

development.

Rafael Hostettler, Roboy Project

Leader, commented: “In software development, rapid development cycles allow

software improvement by testing it ‘in the wild’. Additive Manufacturing allows

us to apply this approach to robotics, enabling a rapid development to find

optimal functional parts in a fraction of the time.” He continues: “EOS’ AM

technology is a key component for doing this as it enables the iterative

hardware development that is crucial for our project.”

Leader, commented: “In software development, rapid development cycles allow

software improvement by testing it ‘in the wild’. Additive Manufacturing allows

us to apply this approach to robotics, enabling a rapid development to find

optimal functional parts in a fraction of the time.” He continues: “EOS’ AM

technology is a key component for doing this as it enables the iterative

hardware development that is crucial for our project.”

Humanoid robotics: A vision with

social impact

social impact

In the future, with the increasing

advances in Artificial Intelligence and robotics, robots will play a much

more prominent role both in society and at work – to the point that especially

dangerous and repetitive tasks can be completed by robots. In this context,

building robots with similar morphology to the human body yields critical

advantages over classical robotic approaches. First and foremost, the human

musculoskeletal system is a proven solution that leads to dexterous, dynamic

and robust robots. In addition, a human-like robot eases interaction between

human and machine significantly, making it more intuitive and natural. Over

centuries humans have adapted the environment to fit their needs, humanoid

robots can therefore fit into this environment more easily – thus avoiding

expensive adaptions. Furthermore, building robots that are compatible with the

human anatomy can help to augment and repair human mobility, with the use of

exoskeletons and prosthetics, for example.

advances in Artificial Intelligence and robotics, robots will play a much

more prominent role both in society and at work – to the point that especially

dangerous and repetitive tasks can be completed by robots. In this context,

building robots with similar morphology to the human body yields critical

advantages over classical robotic approaches. First and foremost, the human

musculoskeletal system is a proven solution that leads to dexterous, dynamic

and robust robots. In addition, a human-like robot eases interaction between

human and machine significantly, making it more intuitive and natural. Over

centuries humans have adapted the environment to fit their needs, humanoid

robots can therefore fit into this environment more easily – thus avoiding

expensive adaptions. Furthermore, building robots that are compatible with the

human anatomy can help to augment and repair human mobility, with the use of

exoskeletons and prosthetics, for example.

Dr. Adrian Keppler, Chief Marketing

Officer (CMO) at EOS, said: “While a larger number of companies focusses on AI

development, only a very small number of projects worldwide develop humanoid

robotics. Therefore, we are all the more proud to support the renowned Roboy

project and see its meaning. As the strengths of Additive Manufacturing lie in

those areas where conventional manufacturing reaches its limitations, EOS’

technology is the ideal solution for a research project as ambitious as Roboy.

We are happy that the Roboy team is trusting in EOS to realize their vision.”

Officer (CMO) at EOS, said: “While a larger number of companies focusses on AI

development, only a very small number of projects worldwide develop humanoid

robotics. Therefore, we are all the more proud to support the renowned Roboy

project and see its meaning. As the strengths of Additive Manufacturing lie in

those areas where conventional manufacturing reaches its limitations, EOS’

technology is the ideal solution for a research project as ambitious as Roboy.

We are happy that the Roboy team is trusting in EOS to realize their vision.”

For the LATEST tech updates,

FOLLOW us on our Twitter

LIKE us on our FaceBook

SUBSCRIBE to us on our YouTube Channel!